Carbon fiber material forming technology overview

Carbon fiber material forming technology overview:

Carbon fiber is generally combined with the substrate (resin, etc.) to be used in the form of composite materials. According to the shape and characteristics of the final product, a variety of molding methods (processing methods) are used. In addition, in order to improve the physical property and appearance, shorten the molding time as the goal, the molding method is becoming more and more perfect.

Carbon fiber is generally combined with the substrate (resin, etc.) to be used in the form of composite materials. According to the shape and characteristics of the final product, a variety of molding methods (processing methods) are used. In addition, in order to improve the physical property and appearance, shorten the molding time as the goal, the molding method is becoming more and more perfect.

The following is a representative carbon fiber molding method:

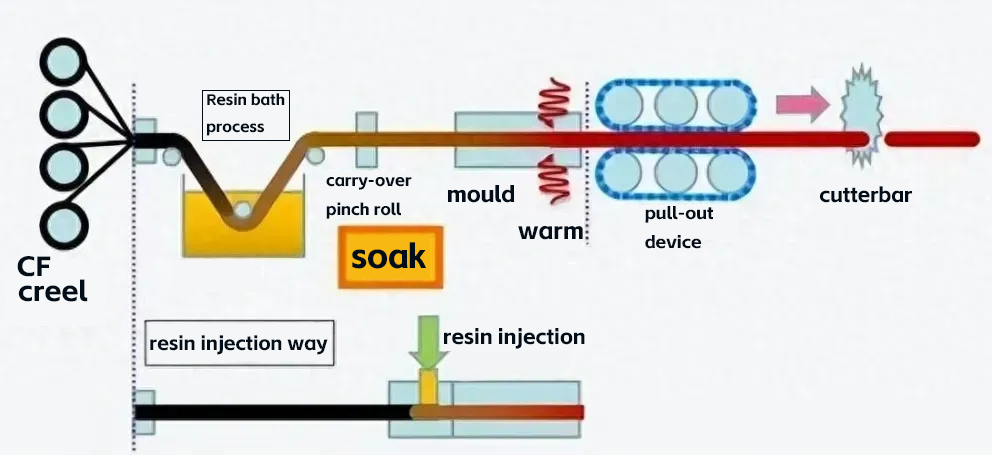

Drawing forming

Filament winding forming

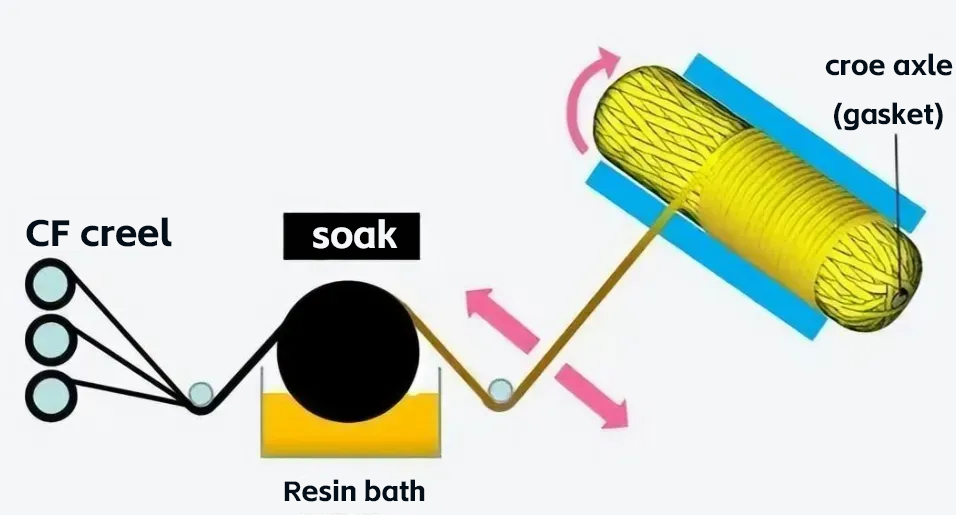

Filament winding forming

This is a process in which carbon fiber strands impregnated with liquid resin are wrapped around a mandlet and then cured by heat. There are two methods, one is the method of winding the carbon fiber while impregnating it in the resin tank (bath), and the other is the method of winding the tow material pre-impregnated in the resin. Suitable for tubular and pot shaped products.

This is a process in which carbon fiber strands impregnated with liquid resin are wrapped around a mandlet and then cured by heat. There are two methods, one is the method of winding the carbon fiber while impregnating it in the resin tank (bath), and the other is the method of winding the tow material pre-impregnated in the resin. Suitable for tubular and pot shaped products.

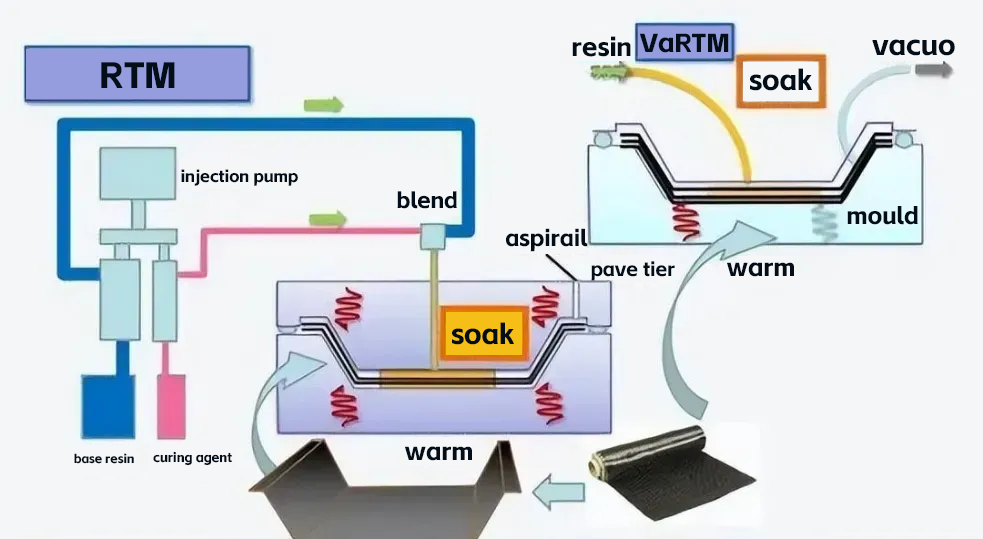

RTM resin transfer molding

This is a method in which a pair of female/male sealed molds are configured with carbon fiber preforming parts (products, fabrics, etc., where carbon fiber is preformed into the shape of a product), liquid resin is pressed into, impregnated, and heated to cure. The method of curing under vacuum pressure using only a negative mold is called VaRTM molding (vacuum assisted RTM). RTM is suitable for small and medium-sized, VaRTM is suitable for large and medium-sized molding products.

This is a method in which a pair of female/male sealed molds are configured with carbon fiber preforming parts (products, fabrics, etc., where carbon fiber is preformed into the shape of a product), liquid resin is pressed into, impregnated, and heated to cure. The method of curing under vacuum pressure using only a negative mold is called VaRTM molding (vacuum assisted RTM). RTM is suitable for small and medium-sized, VaRTM is suitable for large and medium-sized molding products.

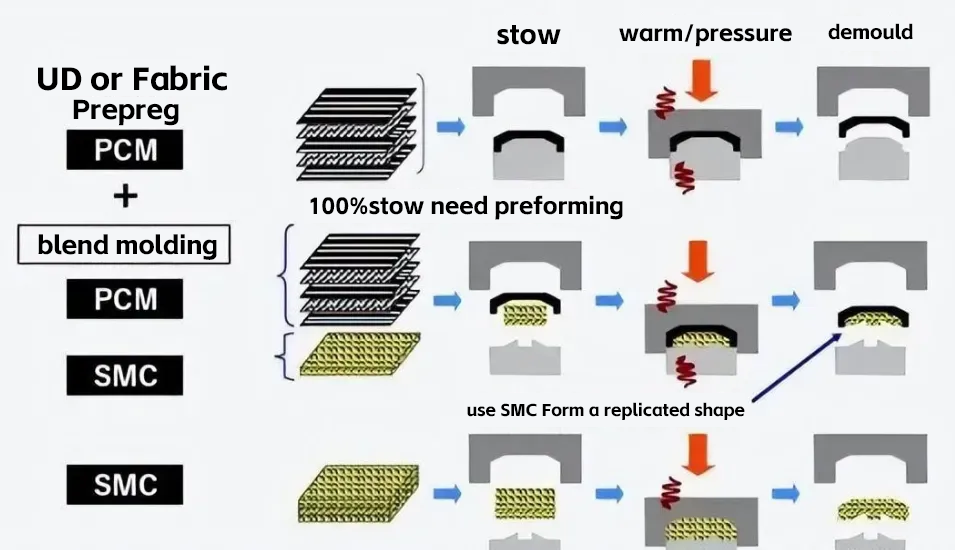

punch forming

This is a method of layering thin sheets of impregnated resin such as prepreg or SMC on a mold and applying pressure while curing with heat. Mitsubishi Chemical has established the PCM(Prepreg molding) forming method based on high cycle and preforming technology, which can also be mixed with SMC materials. The molding method is suitable for a large number of raw products.

This is a method of layering thin sheets of impregnated resin such as prepreg or SMC on a mold and applying pressure while curing with heat. Mitsubishi Chemical has established the PCM(Prepreg molding) forming method based on high cycle and preforming technology, which can also be mixed with SMC materials. The molding method is suitable for a large number of raw products.

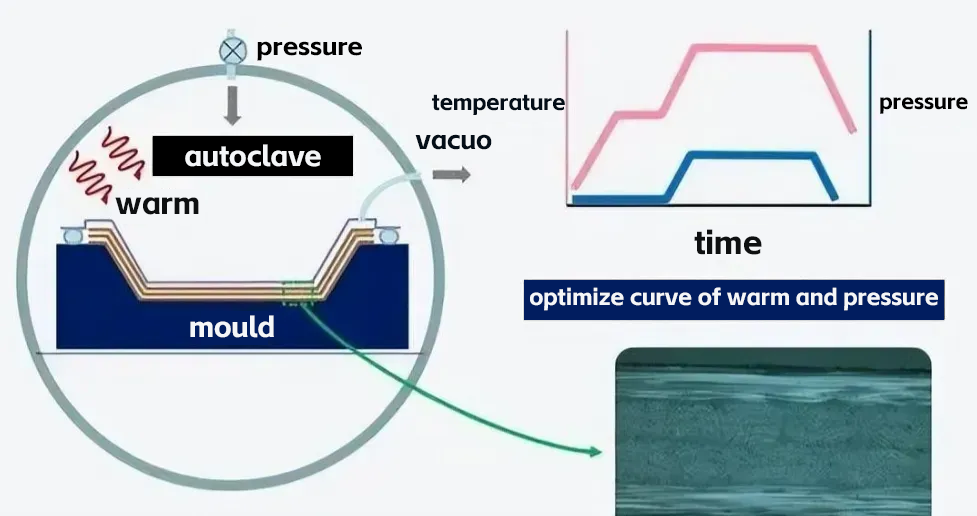

Autoclave (AC) molding

An autoclave is simply a pressure cooker. The prepreg is stacked on the forming die, the expanded film (used to create the vacuum state) is decompressed, and the pressure is applied in the autoclave to heat curing. This molding method is suitable for manufacturing high quality and high performance products, but the cost is high because of the long molding cycle.

An autoclave is simply a pressure cooker. The prepreg is stacked on the forming die, the expanded film (used to create the vacuum state) is decompressed, and the pressure is applied in the autoclave to heat curing. This molding method is suitable for manufacturing high quality and high performance products, but the cost is high because of the long molding cycle.

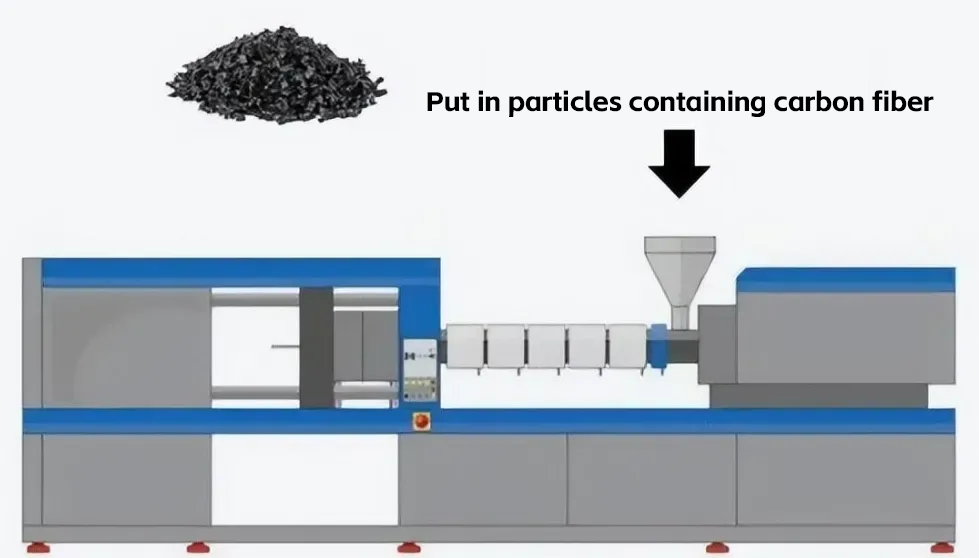

injection moulding

Also known as injection molding, it is a molding method in which thermoplastic resin raw materials (pellets) such as carbon fiber reinforced nylon and polycarbonate are heated and melted, and injected into the mold cavity (gap). The mechanical properties will be reduced, but this is a molding method suitable for short cycle, complex shape molding.

Also known as injection molding, it is a molding method in which thermoplastic resin raw materials (pellets) such as carbon fiber reinforced nylon and polycarbonate are heated and melted, and injected into the mold cavity (gap). The mechanical properties will be reduced, but this is a molding method suitable for short cycle, complex shape molding.